Hot Melt glue is melted plastic that squirts out of a hot gun. The hot glue is supposed to bring enough heat to the surfaces to be glued to make the primary surface (like the wall of your dollhouse), the secondary surface (maybe a log or a piece of trim), and the glue all above the melting temperature of the glue all at the same time - and for it to still be that hot at the moment the joint is pressed together.

Get it hot

For this reason, high-temperature hot melt glue guns generally stick better - the glue comes out hotter (400 - 450 degrees F) so it brings more heat to the surfaces to be joined. 'Low Temp' glues (200 - 250F) deliver less heat to the surface, so they can't heat up the surfaces to be joined as well and, if any cooling happens before the surfaces are pressed together, may not get them hot enough to stick at all.

Keep it hot

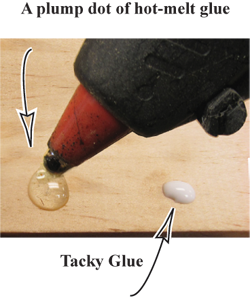

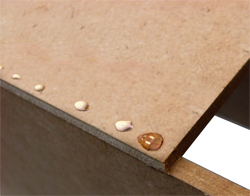

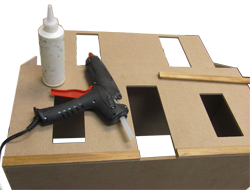

The first technique to use hot-melt glue effectively is to keep it from cooling so much. A fat puddle of glue stays hot a long time, but it's seldom the right amount of glue to stay hidden in the joint. A fat worm of glue is perfect if the glue surface is large enough for it to spread out, and it will bring more heat to the surfaces than a squiggle of glue around the edges (which hardly has a chance of sticking at all). But the real convenience of Hot Melt glue is unleashed when you put dots of tacky glue on a piece of trim, then plump dots of Hot Glue in the few places required to hold the Trim flat while the white glue dries.

Dots of Tacky Glue and then a plump dot of Hot Melt Glue every so often (on a Trimstrip, maybe every 4 - 6 inches) lets you put the Hot Melt on last so it has less time to cool, but best of all, it gives you a place to hold the Trimstrip where you won't get burned (in between the 'plump dots')

(Not getting burned - very important!)

Deliver heat to the joint

Another way to get the surfaces hot for gluing is to pre-heat with a hot-air gun or hair dryer. In fact, it's a useful technique to take off a Trimstrip by heating it with a hair dryer, and to leave the glue in place so you can re-heat both surfaces and press it back together when you are done.

I do this most often when a repair comes to me with falling-off Trim that was glued with a string of 'something' melt glue (probably cool-melt because it's pretty hard to glue with a string of hot melt without burning yourself), and I can just heat both surfaces well with my 1800 watt hair dryer, and press the joint back together - fixed, and better than new!

heating both surfaces: Repairs

Speed counts:

Once you’ve put those plump dots where they are needed, the glue begins to cool, and the more heat in the glue, the better. So test the part in position, then apply dots of Tacky Glue, and then put plump dots of Hot Melt only where they are needed to hold the joint tight while the Tacky Glue dries. Here's a video.

... I've got work to do.

Gary